- HOMEABOUT USQUALITYTECHNOLOGYMATERIALS

- WOODMETALPVC AND DRYWALLCONCRETENEWSROOM

- UpdatesVideo

THE PILLARS OF OUR QUALITY:

THE PILLARS OF OUR QUALITY:

COMPLIANCE-PERFORMANCE-DISTINCTIONTHE PILLARS OF OUR QUALITY:

COMPLIANCE

PERFORMANCE

DISTINCTIONAmbrovit is characterized by three essentials, interconnected, and harmonized values , creating a distinctive presence in a global market and a challenging economic context.

COMPLIANCEExplore our certificationsCommitment to quality is a priority permeating every aspect of the company. This commitment led us to achieve certification for the Quality Management System in 2011.

PERFORMANCEExplore the wide range of certified productsWe have one goal: to achieve excellence in each of the reference sectors of our products, ensuring international certification and meeting the needs of an ever-expanding clientele.

DISTINCTIONAesthetic and durable finishesAmbrovit’s dedication to quality translates into refined process optimization, involving a wide range of products and offering customization options in both aesthetic finishes and galvanic processes. This results in unique solutions designed to withstand the time passing.

QUALITY IS NOT JUST A NOTION.Over time, quality has become a fundamental driver involving every department and led the company to achieve Quality Management System certification in 2011. Most products are equipped with various certifications depending on their type and intended use. Additional quality control tests are conducted in-house in our internal laboratory in collaboration with the University of Trento.

Ambrovit has achieved ISO 9001 certification, a recognition of quality and safety. To attain this certification, the company must demonstrate adherence to criteria such as advanced quality control, regulatory compliance, use of high-quality materials, product safety, and environmental commitment. Sustaining the certification demands a continuous dedication to improvement. This seal of approval serves as a robust indicator of reliability and quality, capable of bolstering customer confidence.

TÜV SÜD conducts periodic surveillance audits on all production processes, ensuring compliance with all requirements mandated by international regulations. Among these, the Euronorm 14592 is particularly relevant, and involves wood structures and connecting cylindrical elements. The standard outlines requirements and testing methods for materials, geometry, strength, rigidity, and durability of connecting cylindrical elements used in load-bearing wooden structures. ISO 9001 certification serves as a seal of approval that highlights a manufacturing company’s consistent commitment to providing products of the highest quality, safety, and reliability. These products adhere to current regulations and are at the forefront of the industry. This recognition becomes a powerful marketing tool, assuring buyers that the products have undergone rigorous quality checks by an international organization.LEARN MORE

TÜV SÜD conducts periodic surveillance audits on all production processes, ensuring compliance with all requirements mandated by international regulations. Among these, the Euronorm 14592 is particularly relevant, and involves wood structures and connecting cylindrical elements. The standard outlines requirements and testing methods for materials, geometry, strength, rigidity, and durability of connecting cylindrical elements used in load-bearing wooden structures. ISO 9001 certification serves as a seal of approval that highlights a manufacturing company’s consistent commitment to providing products of the highest quality, safety, and reliability. These products adhere to current regulations and are at the forefront of the industry. This recognition becomes a powerful marketing tool, assuring buyers that the products have undergone rigorous quality checks by an international organization.LEARN MOREETA (European Technical Assessment) certification is a European process of technical evaluation that assesses and approves the suitability of construction products in compliance with European regulations. This procedure is particularly relevant for the building and construction industry. The ETA certification process involves a comprehensive technical assessment by notified bodies, which examine products based on technical requirements and performance criteria.

ETA certification is voluntary and serves as a way to demonstrate product compliance with European technical specifications, especially when CE standard regulations are not directly applicable or complete.

ETA certification is voluntary and serves as a way to demonstrate product compliance with European technical specifications, especially when CE standard regulations are not directly applicable or complete.

Ambrovit proudly holds the ETA 16/0381 Certification for its entire range of carpentry screws, the ETA 18/1065 Option 1 Certification for anchoring screws in concrete, and the Post R Certificate of Conformity and Safety.

Once an ETA certification is obtained, products can be marketed in all European Union countries, facilitating their acceptance in the European market and transparently showcasing compliance with required technical standards. ETA certification is essential to ensure the quality and safety of construction products and to promote the free movement of goods within the EU.LEARN MOREPRODUCTS CERTIFICATIONSInternational complianceQuality in Ambrovit is a value that must be measured and confirmed through certifications issued by international certifying agency.

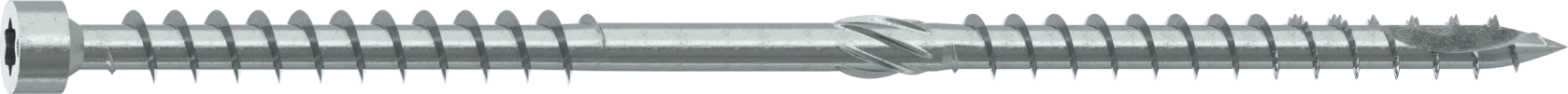

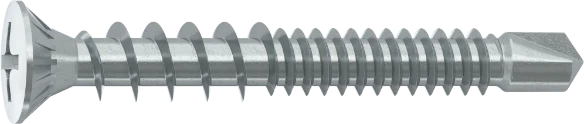

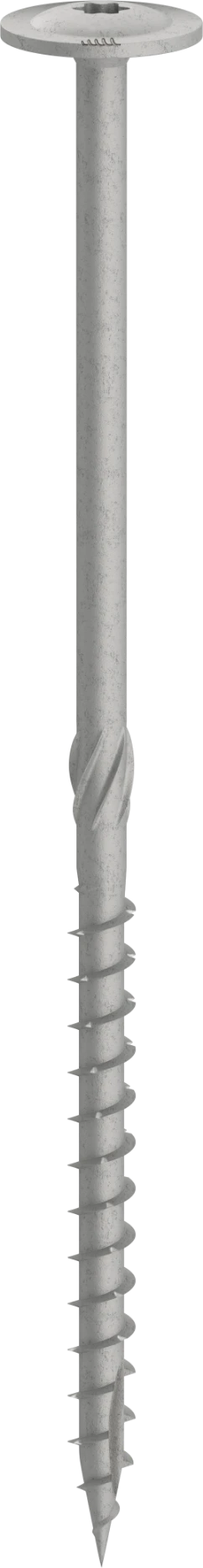

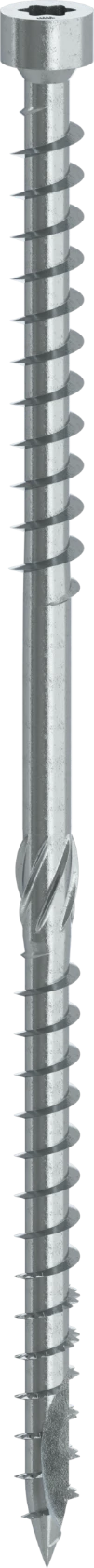

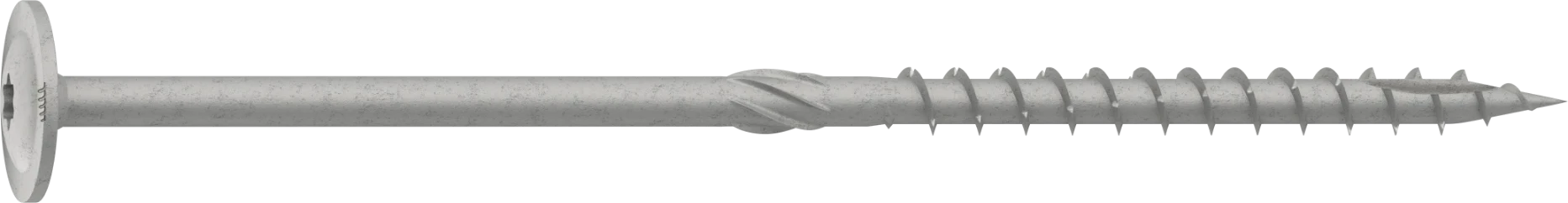

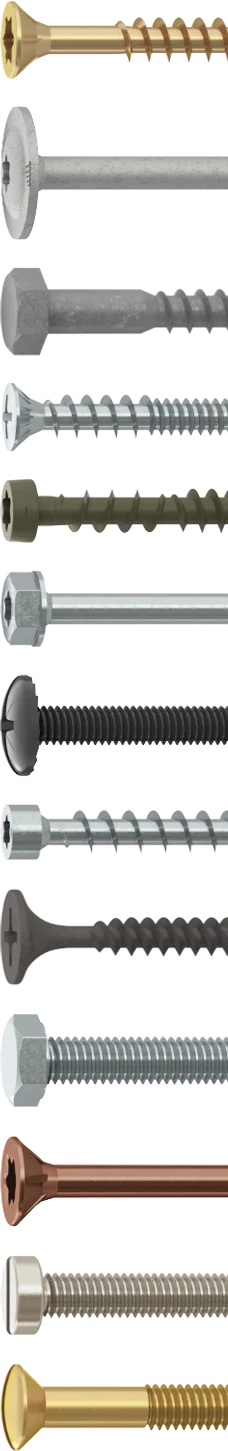

The whole range of products is tested, both the different types of screws and bolts as well as the different finishes and treatments.18,000+CERTIFIED REFERENCESAmong our certifications, it’s included the Euronorm 14592, which provides dimensional parameters, tests to be performed, and quality control procedures that the product must meet to be declared compliant and marked with CE. The company also holds ETA Certification 16/0381 for the entire range of carpentry screws; ETA Certification 18/1065 Option 1 for anchoring concrete screws.REGULATIONSWithin the technical standards of industrial sectorsFastening elements have the task of transferring loads to the supporting material in which they are installed. Therefore, the standardization and conformity of each individual element become fundamental. Let’s see what the main ones are and how they differ from each other.DINIt is a technical standard issued by the German Deutsches Institut für Normung, which means that there is no obligation of application. Essentially, they are private standards with a recommendation character.UNIIt is the acronym for the Italian National Unification Body, a private association that develops and publishes technical standards for all industrial sectors. It represents Italy in European (CEN) and global (ISO) standardization organizations.ISOIt is the acronym that identifies standards developed by ISO, the International Organization for Standardization. These standards are applicable worldwide. Each country can decide whether to adopt them as national standards.GALVANIC TREATMENTSOur galvanic treatments ensure reliable performance in outdoor environments and challenging conditions.AESTHETIC FINISHESElegance and design: aesthetic finishes add a touch of style to every project without compromising durability and performance.

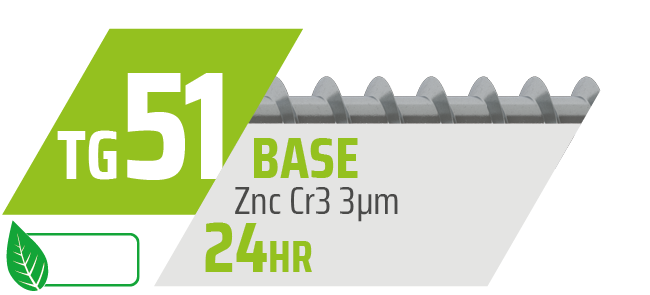

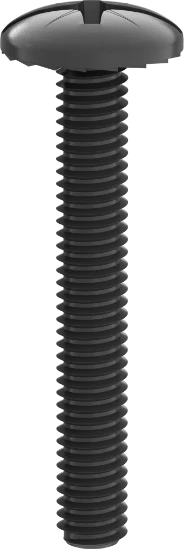

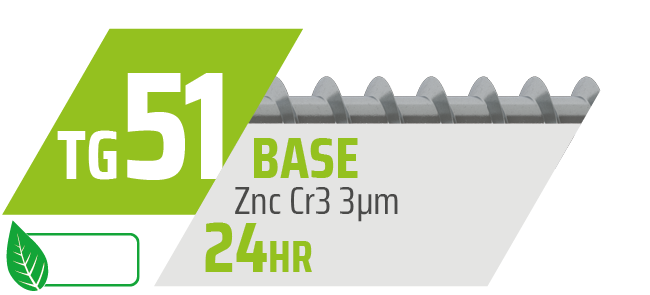

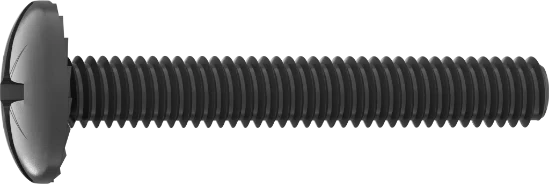

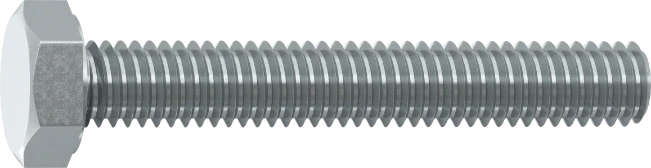

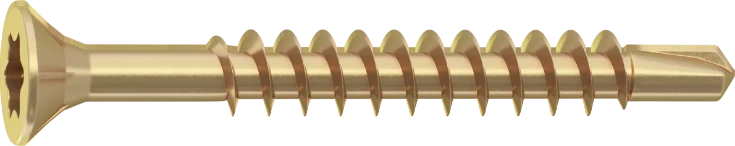

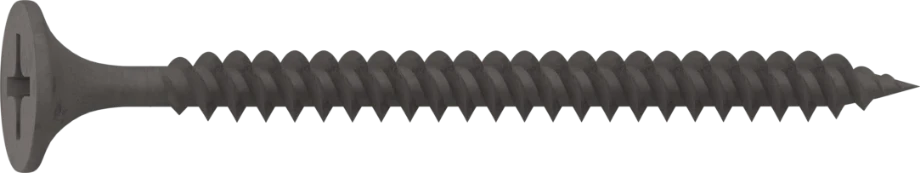

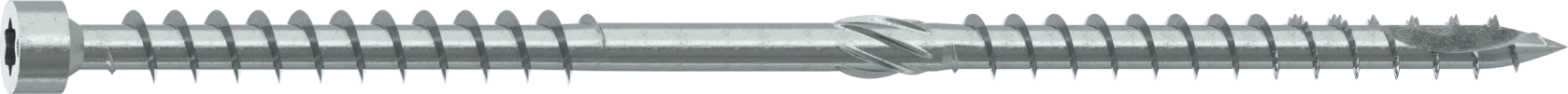

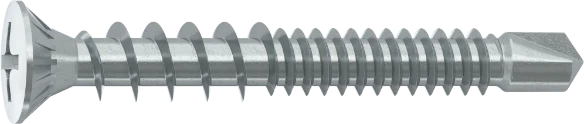

40µm HOT DIP GALVANIZED“Hot Dip Galvanized” is the hot-dip galvanizing process by immersion in molten zinc. This specification makes the screws highly resistant to corrosion, as in external structures, bridges, maritime structures, and other applications in challenging environments.400hr HIGH TOPThrough special treatments, these screws with a resistance of 400 hours are an excellent choice for applications that require reliable protection against corrosion in humid environments or exposure to corrosive substances.120hr TOPWith a thicker zinc layer of 8 microns, the corrosion resistance in hours increases. In this case, “120 hr” indicates that the screws have been designed to withstand corrosion in a standard test environment for at least 120 hours.72hr MEDIUMThe CR3 zinc coating is designed to provide good corrosion resistance in many applications, while a thicker zinc layer of more than 5 microns can offer better corrosion protection.48hr PHOSPHATEDPhosphated finish is a surface coating often used for screws and other metal components. The final result is not known to be aesthetically appealing or decorative, but mainly to provide anti-corrosion and anti-friction functions.36hr YELLOWYellow zinc plating is a variation of the zinc plating process that uses a special passivate to achieve a yellow color on the zinc-coated surface. This type of finish is often used for aesthetic purposes or for visual recognition of components.24hr BASEA 3-micron finish is considered thick enough for effective corrosion protection in many applications. A thicker zinc layer provides better protection and resistance.BLACKZNC CR3″ is a specification indicating that the screws have been zinc-coated with a layer of zinc (ZNC) according to a standard that provides moderate corrosion resistance (CR3). This type of finish is commonly used to protect screws in normal environments.The RoHS directive, staying for Restriction of Hazardous Substances, is a European law that limits the use of certain harmful substances in the manufacturing of commercial products. This regulation safeguards the quality of life and the environment by reducing the content of harmful substances such as lead, mercury, cadmium, and others. Compliance with the RoHS directive is synonymous with quality for marketing products in the European Union, thereby contributing to the promotion of the adoption of safer and more sustainable technologies.

40µm HOT DIP GALVANIZED“Hot Dip Galvanized” is the hot-dip galvanizing process by immersion in molten zinc. This specification makes the screws highly resistant to corrosion, as in external structures, bridges, maritime structures, and other applications in challenging environments.400hr HIGH TOPThrough special treatments, these screws with a resistance of 400 hours are an excellent choice for applications that require reliable protection against corrosion in humid environments or exposure to corrosive substances.120hr TOPWith a thicker zinc layer of 8 microns, the corrosion resistance in hours increases. In this case, “120 hr” indicates that the screws have been designed to withstand corrosion in a standard test environment for at least 120 hours.72hr MEDIUMThe CR3 zinc coating is designed to provide good corrosion resistance in many applications, while a thicker zinc layer of more than 5 microns can offer better corrosion protection.48hr PHOSPHATEDPhosphated finish is a surface coating often used for screws and other metal components. The final result is not known to be aesthetically appealing or decorative, but mainly to provide anti-corrosion and anti-friction functions.36hr YELLOWYellow zinc plating is a variation of the zinc plating process that uses a special passivate to achieve a yellow color on the zinc-coated surface. This type of finish is often used for aesthetic purposes or for visual recognition of components.24hr BASEA 3-micron finish is considered thick enough for effective corrosion protection in many applications. A thicker zinc layer provides better protection and resistance.BLACKZNC CR3″ is a specification indicating that the screws have been zinc-coated with a layer of zinc (ZNC) according to a standard that provides moderate corrosion resistance (CR3). This type of finish is commonly used to protect screws in normal environments.The RoHS directive, staying for Restriction of Hazardous Substances, is a European law that limits the use of certain harmful substances in the manufacturing of commercial products. This regulation safeguards the quality of life and the environment by reducing the content of harmful substances such as lead, mercury, cadmium, and others. Compliance with the RoHS directive is synonymous with quality for marketing products in the European Union, thereby contributing to the promotion of the adoption of safer and more sustainable technologies.

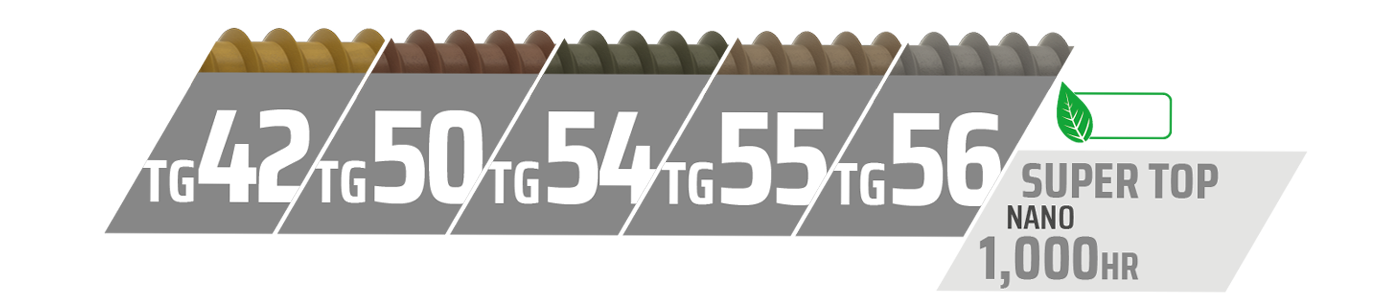

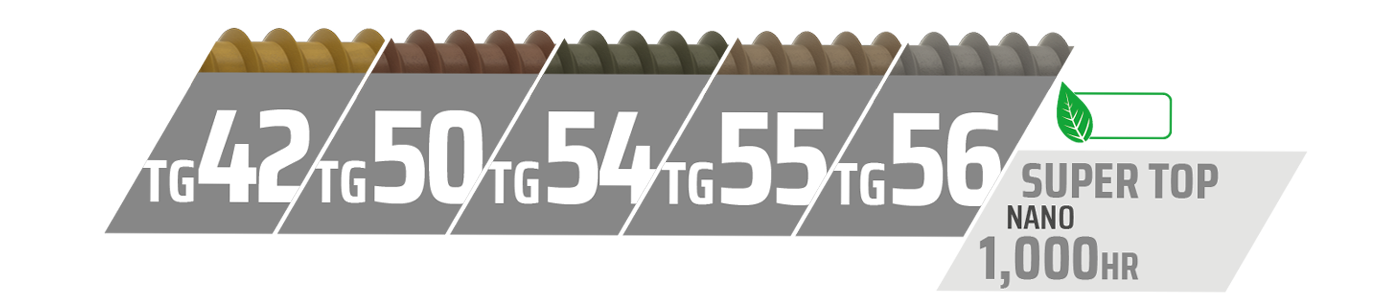

1,000 hrResistance finishes

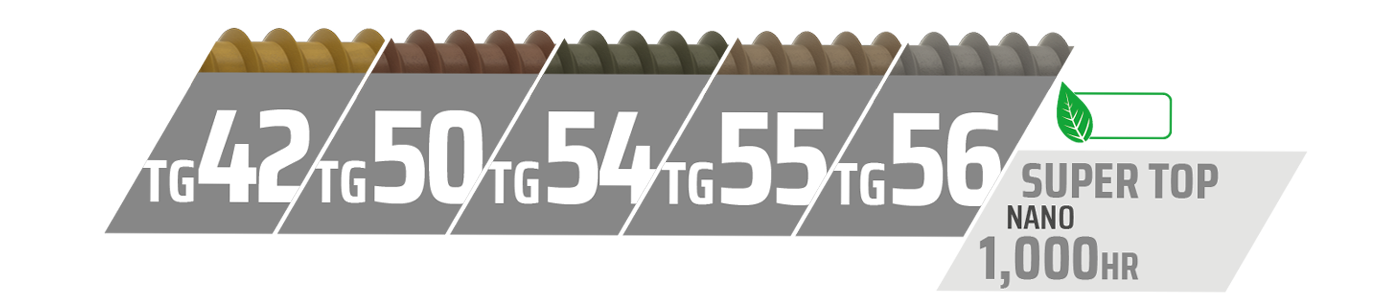

1,000 hrResistance finishesSpecial treatment Enduro 1,000h, with a non-organic three layers ceramic coating, for a high resistance to corrosion. This finish guarantees within 1000h of salt spray resistance, in compliance with ISO 9227 standard, and enhance the performance of the screw itself.

15 µm of nano treatment5 µm of anti-abrasive layer5-8 µm of white zinc coating Cr3 treatmentSteel substrateNANO COATINGIt is a non-organic tri-layer coating with a nano-treatment, an anti-abrasion layer, and a white zinc coating for high resistance to salt spray corrosion.10 µm of baked ceramic coating~2 µm high-corrosion-resistance chemical conversion film3-5 µm Metallic zinc layerSteel substrateENDURO COATINGIt is a non-organic tri-layer ceramic coating for high resistance to salt spray corrosion, consisting of fired ceramic coating, high corrosion resistance chemical conversion film, and a metallic zinc layer on the steel substrate.AESTHETIC FINISHES FOR YOUR EXCELLENCE PROJECTSAesthetic finishes embody the fusion of resistance and design. From innovative coatings to advanced material solutions, we delve into the details of finishes that stand out for elegance, resilience, and superior performance. Here are our options that allow you to add a touch of style while preserving the quality of your projects, reflecting your vision and ensuring lasting and extraordinary results.SUPER TOP ENDURO FINISHThis type of finish is primarily designed to provide exceptional corrosion resistance (1000 hours in salt spray), however, the finish presents an uniform and clean surface, without traces of corrosion or oxidation, which positively contributes to the aesthetic appearance of the screws. The main priority of this finish is corrosion resistance.

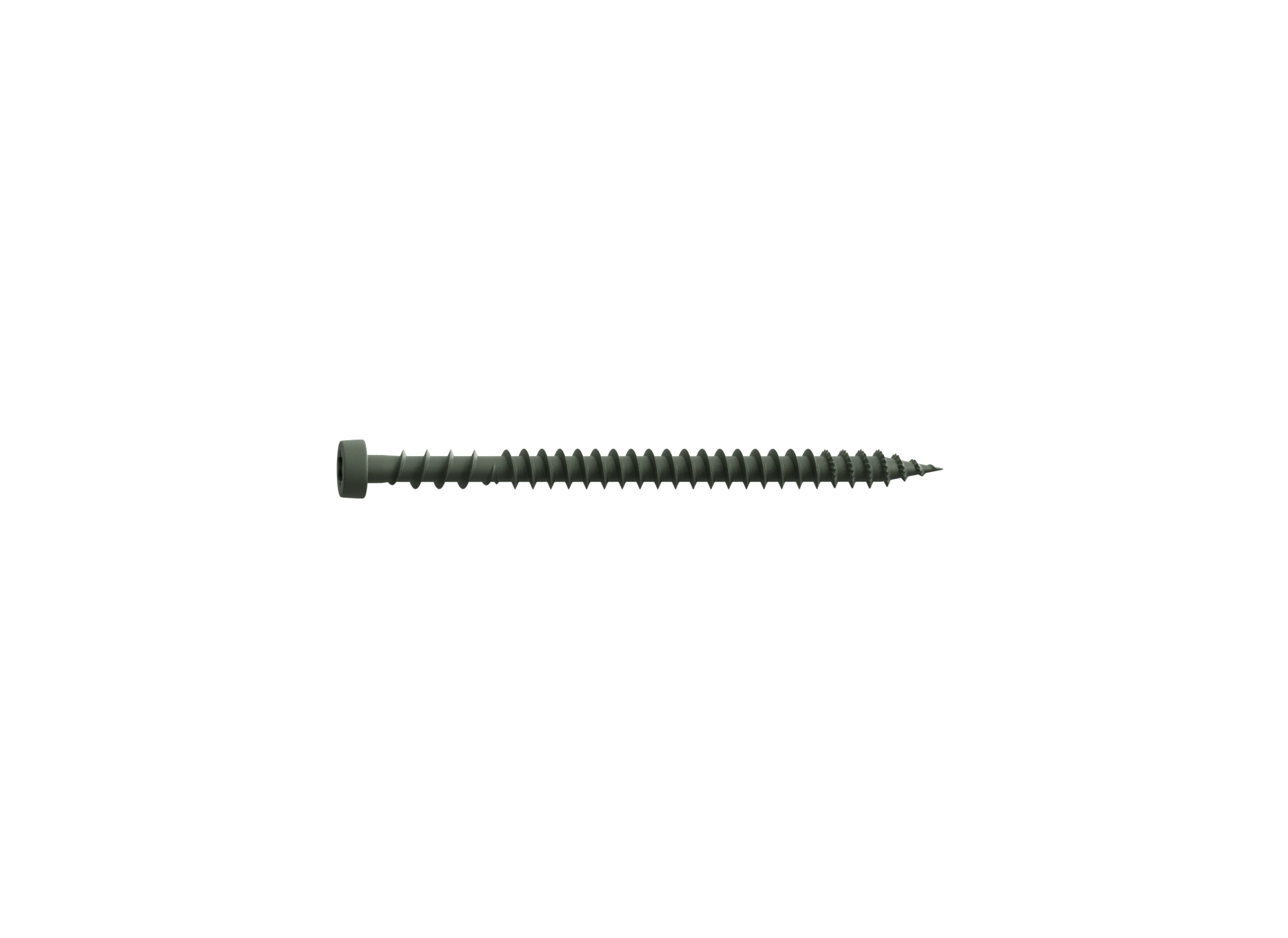

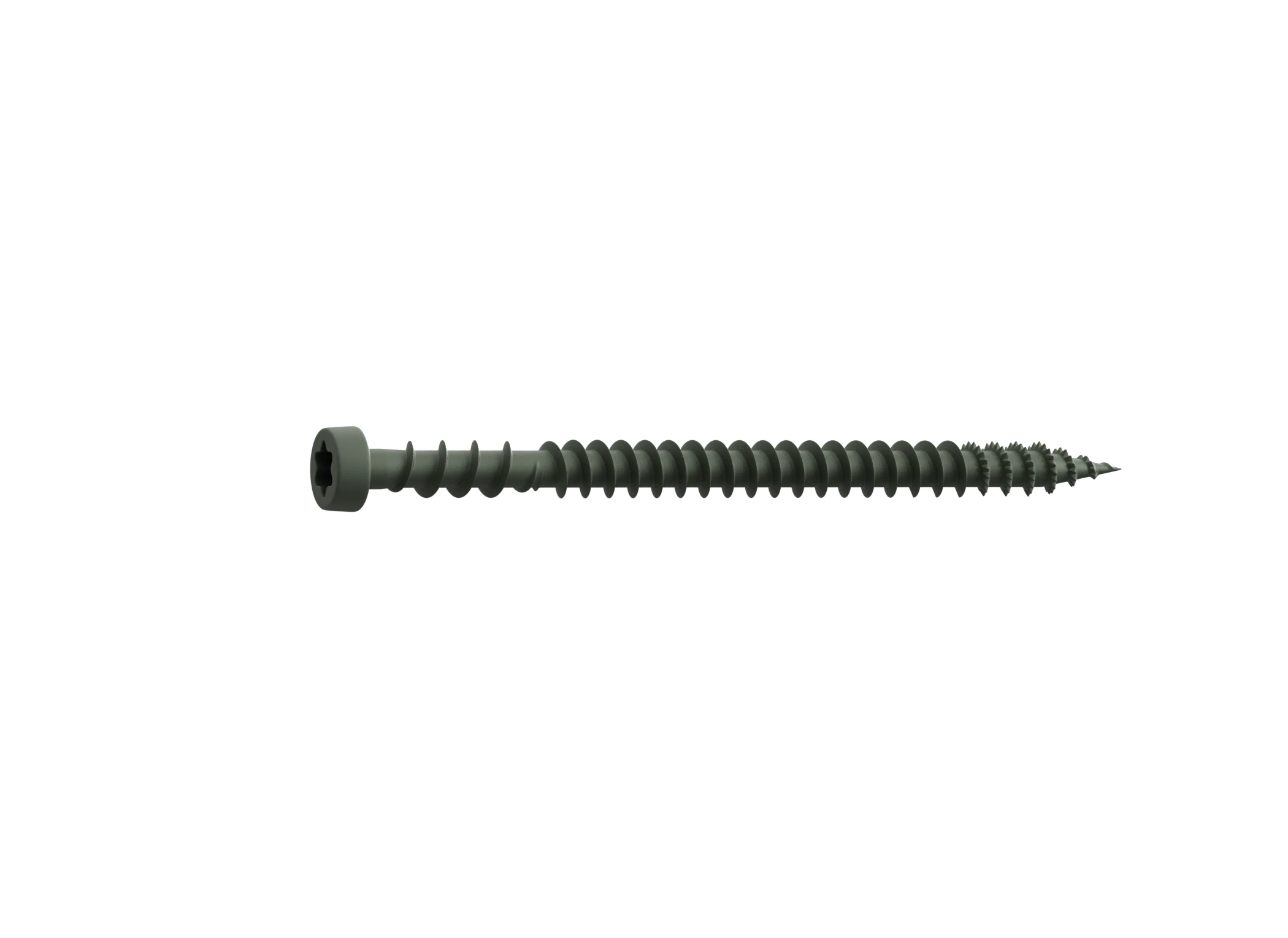

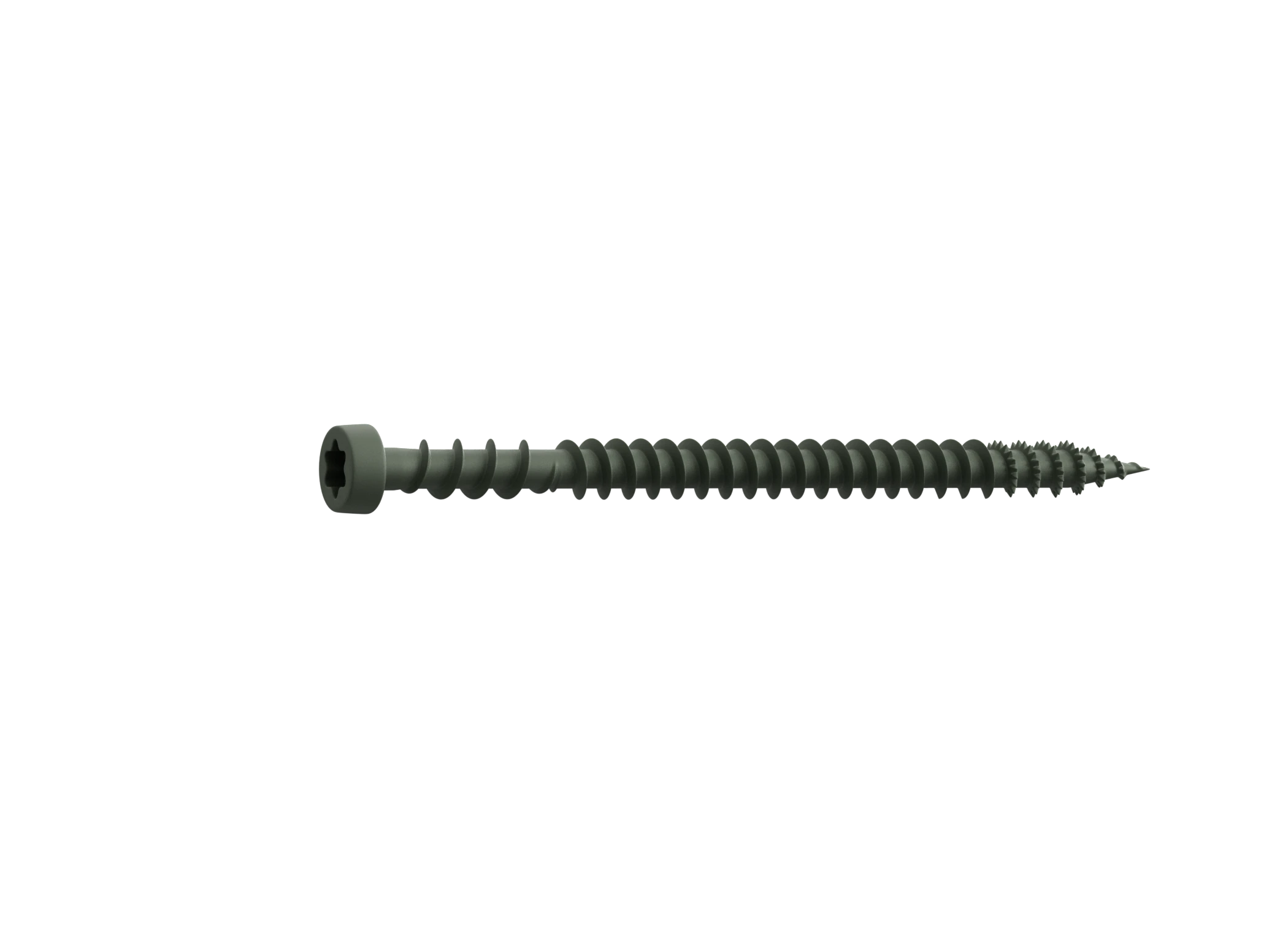

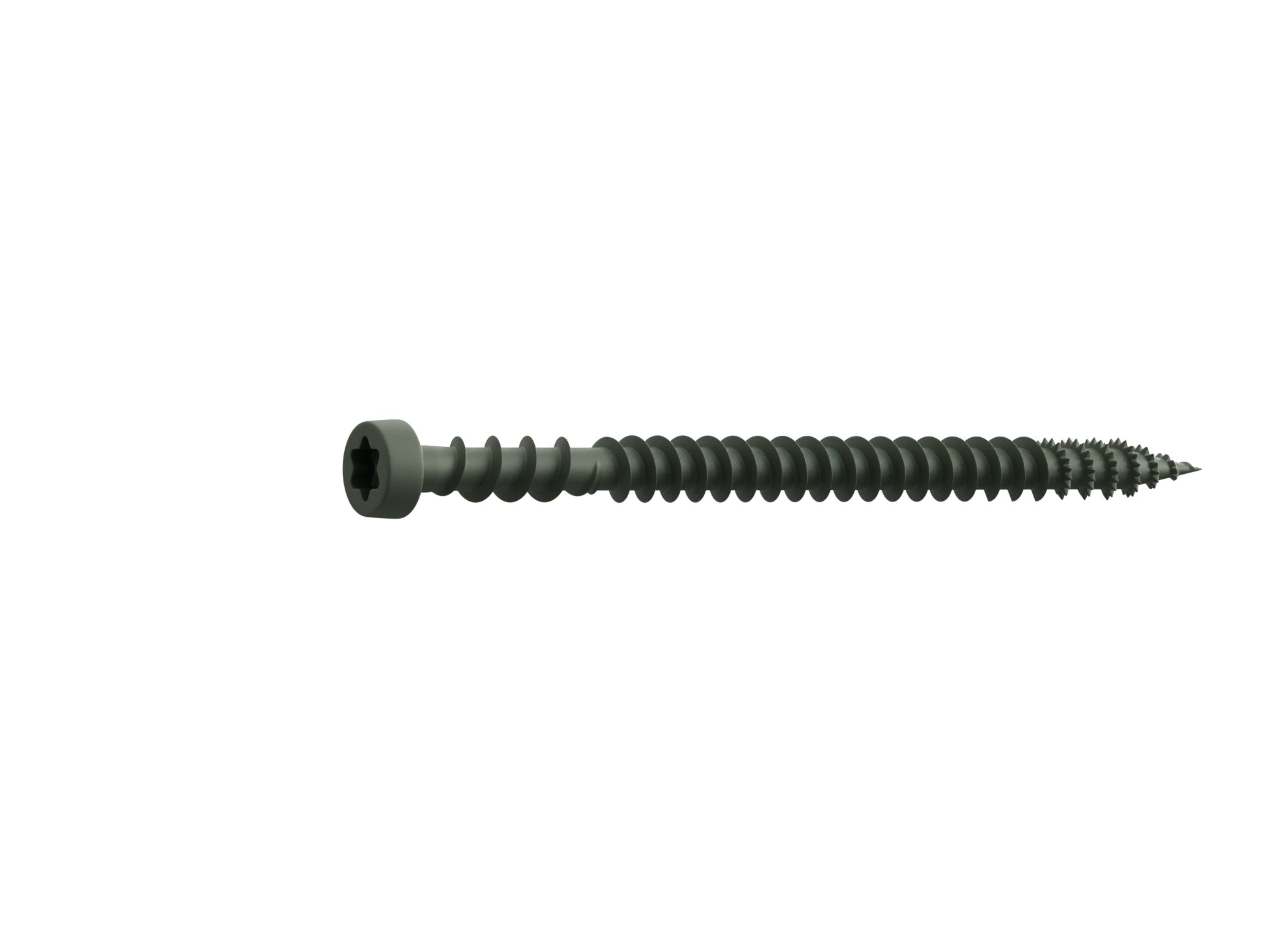

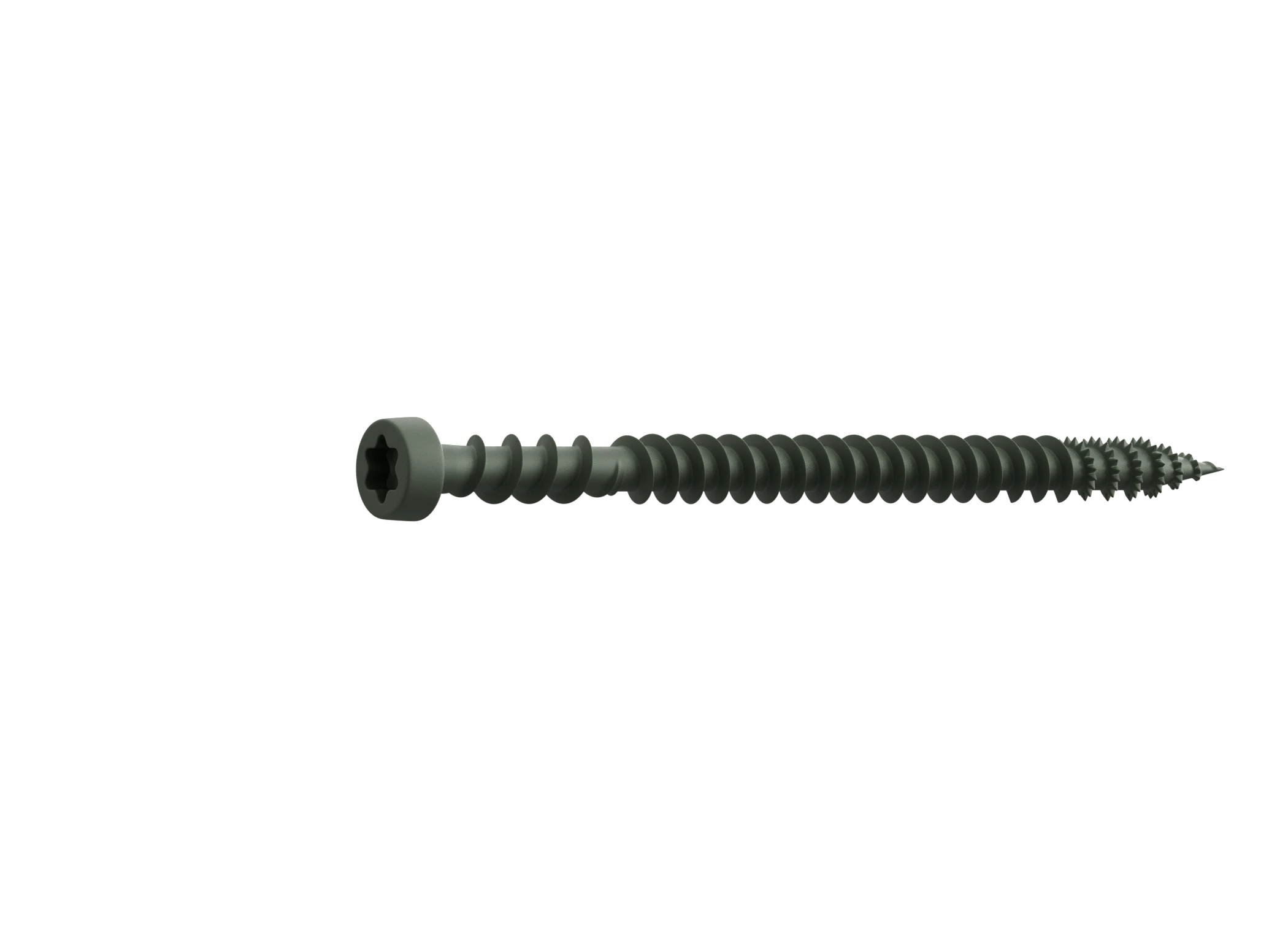

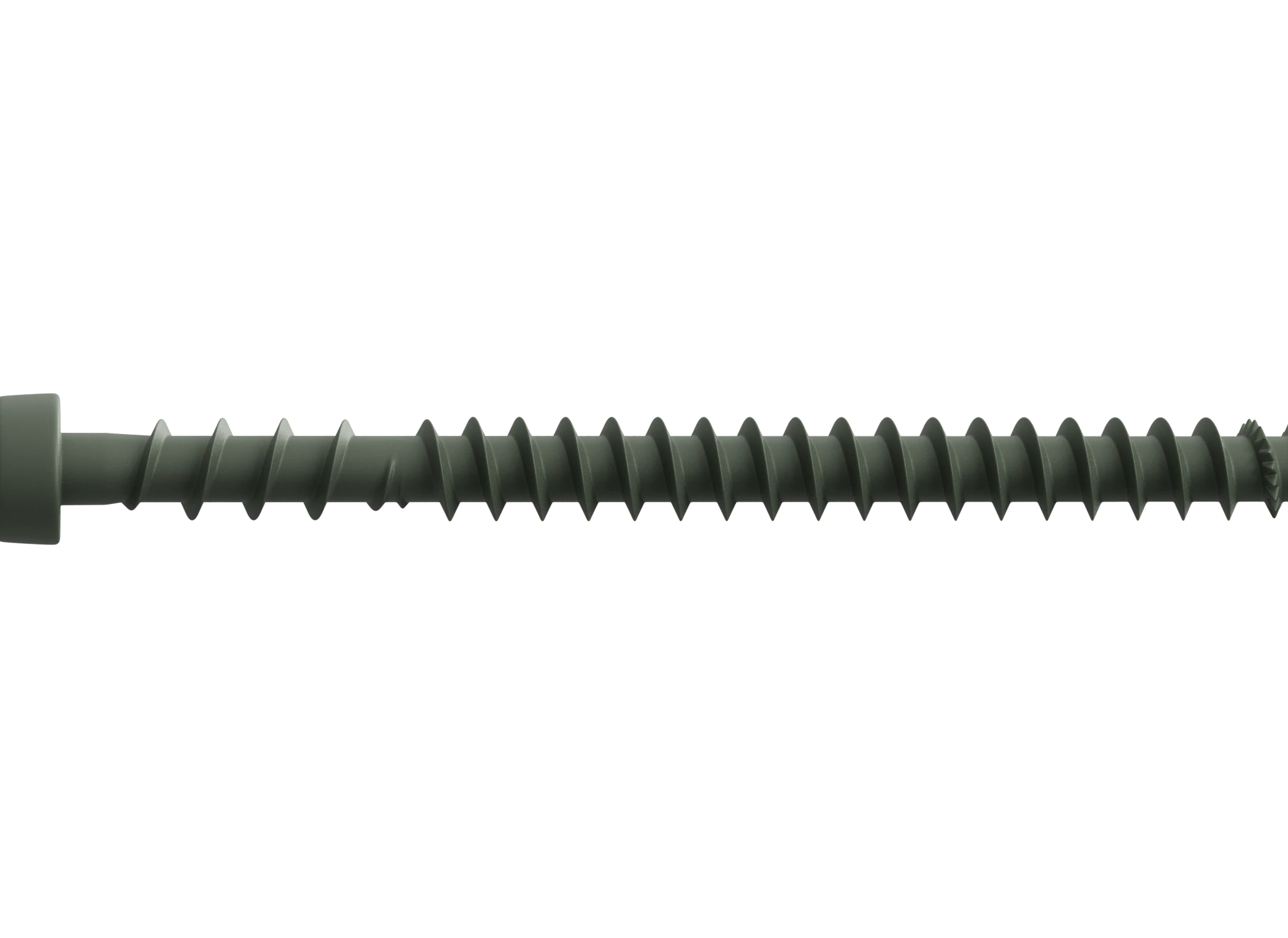

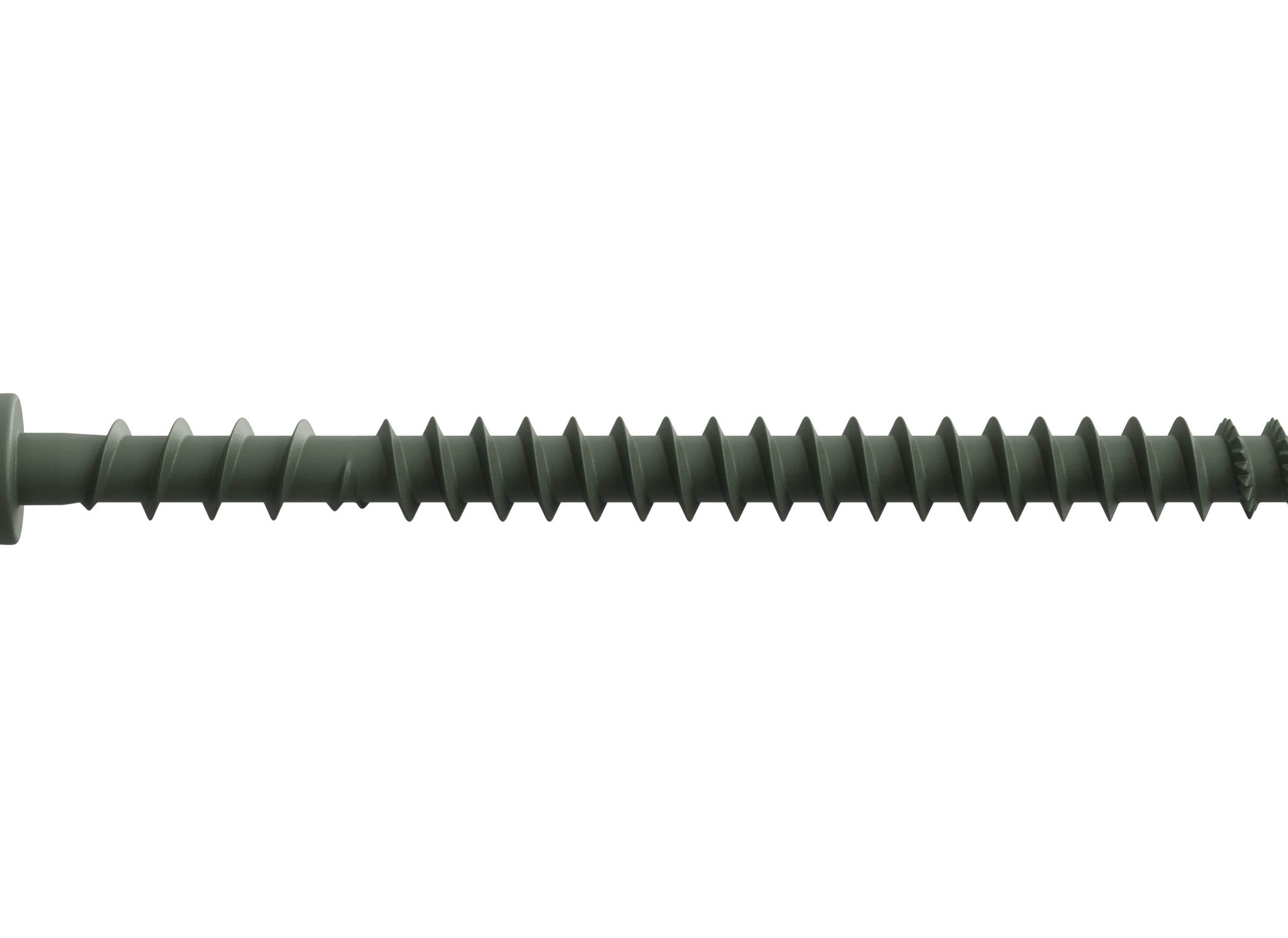

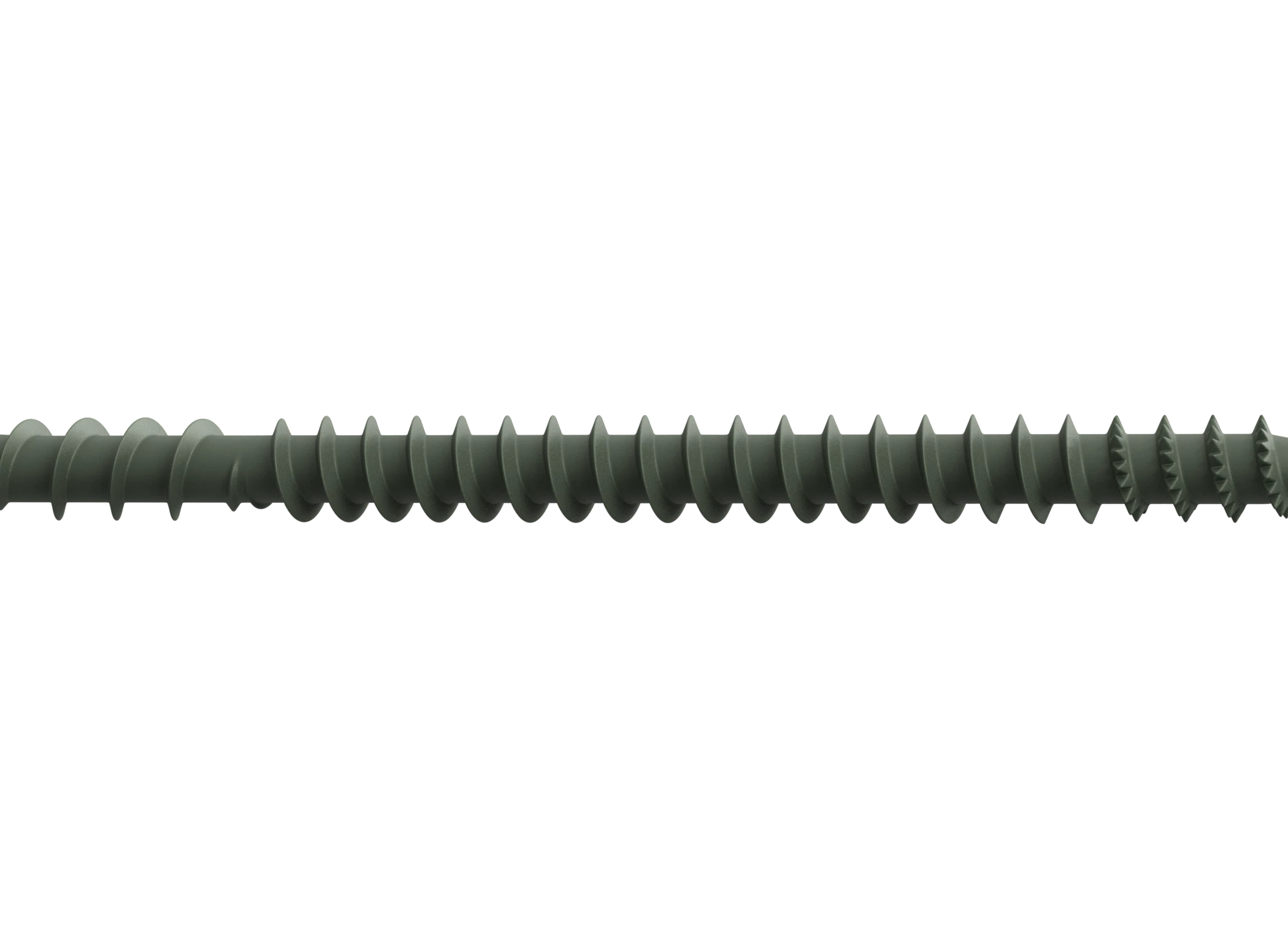

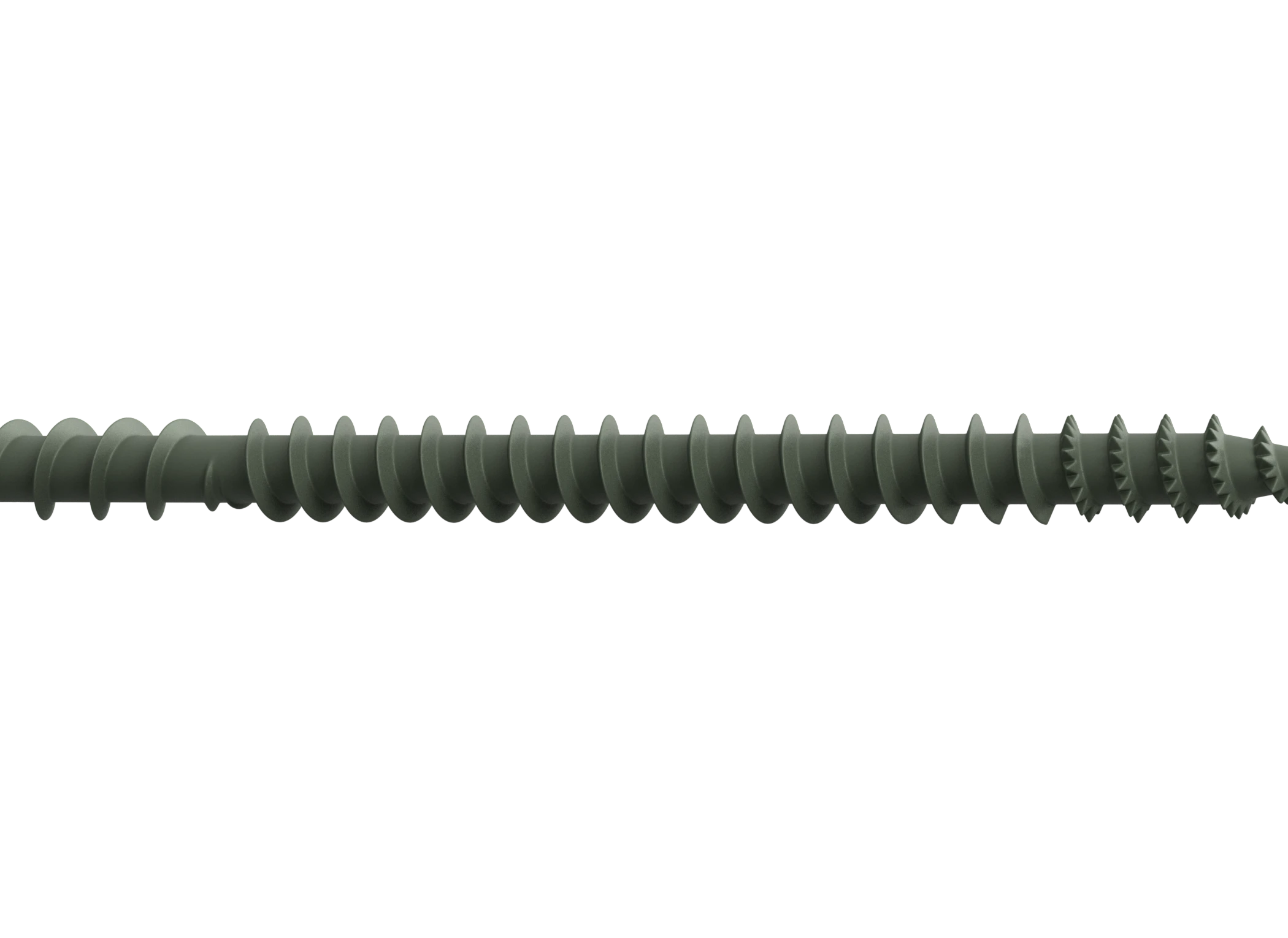

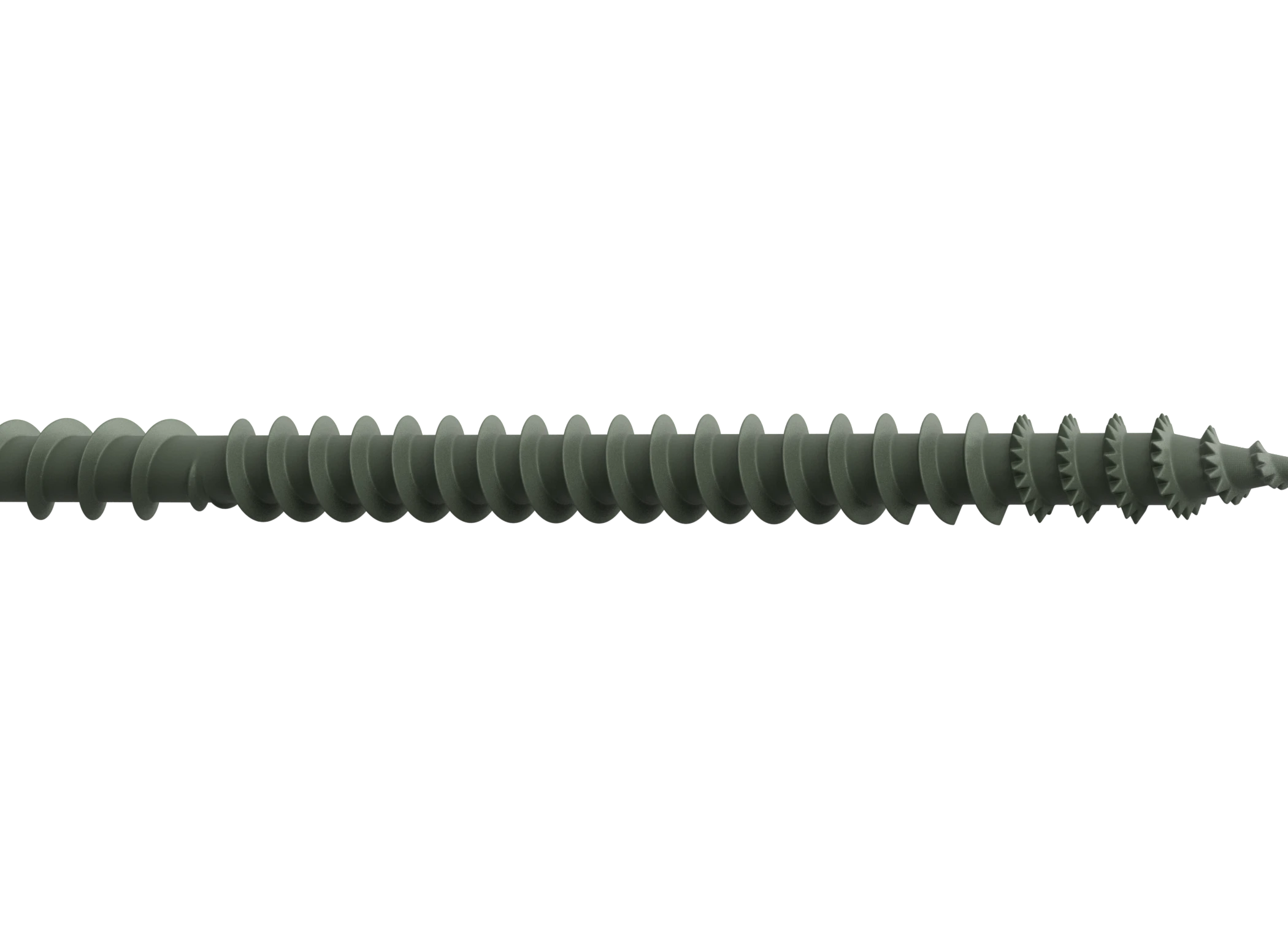

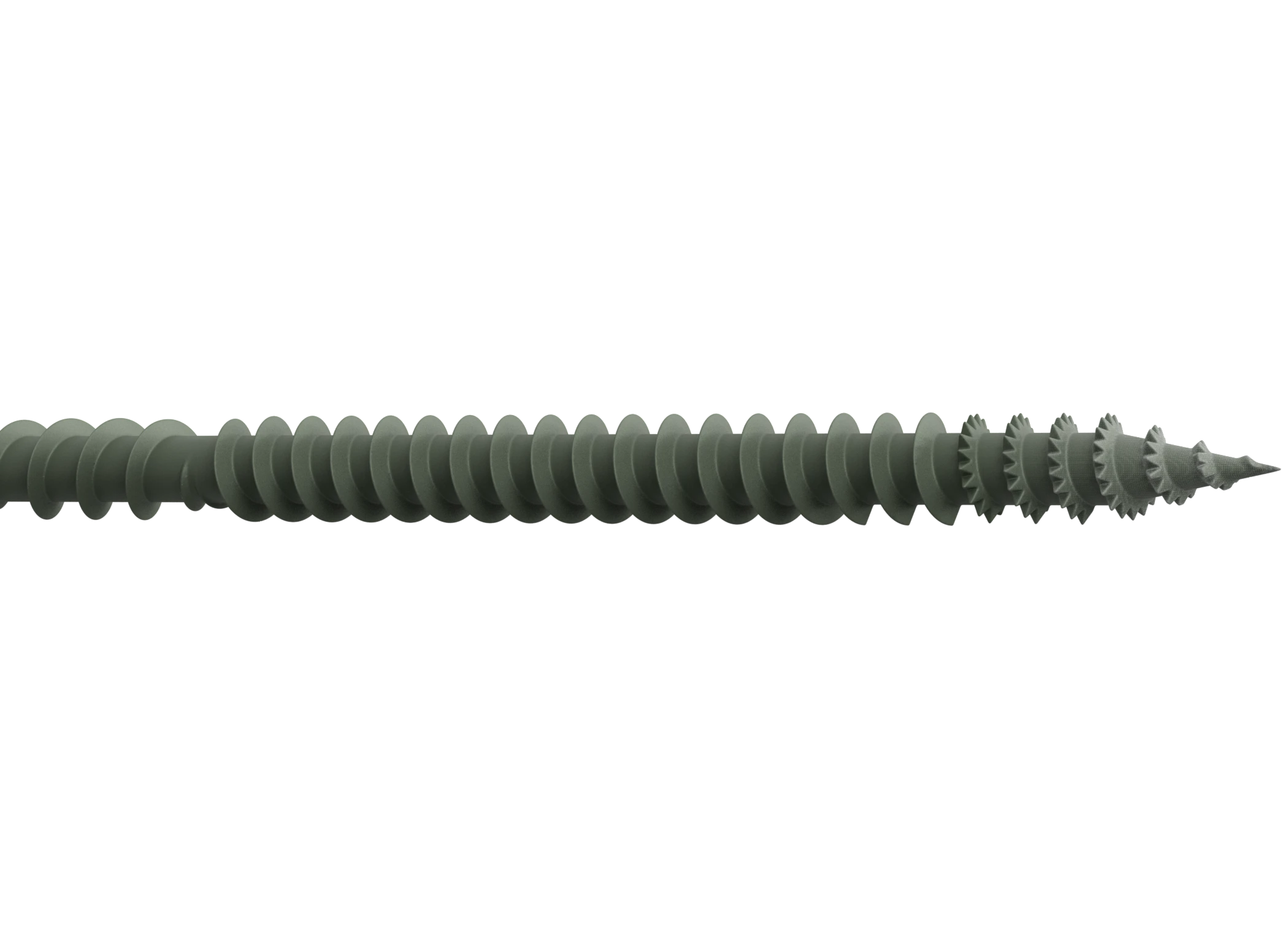

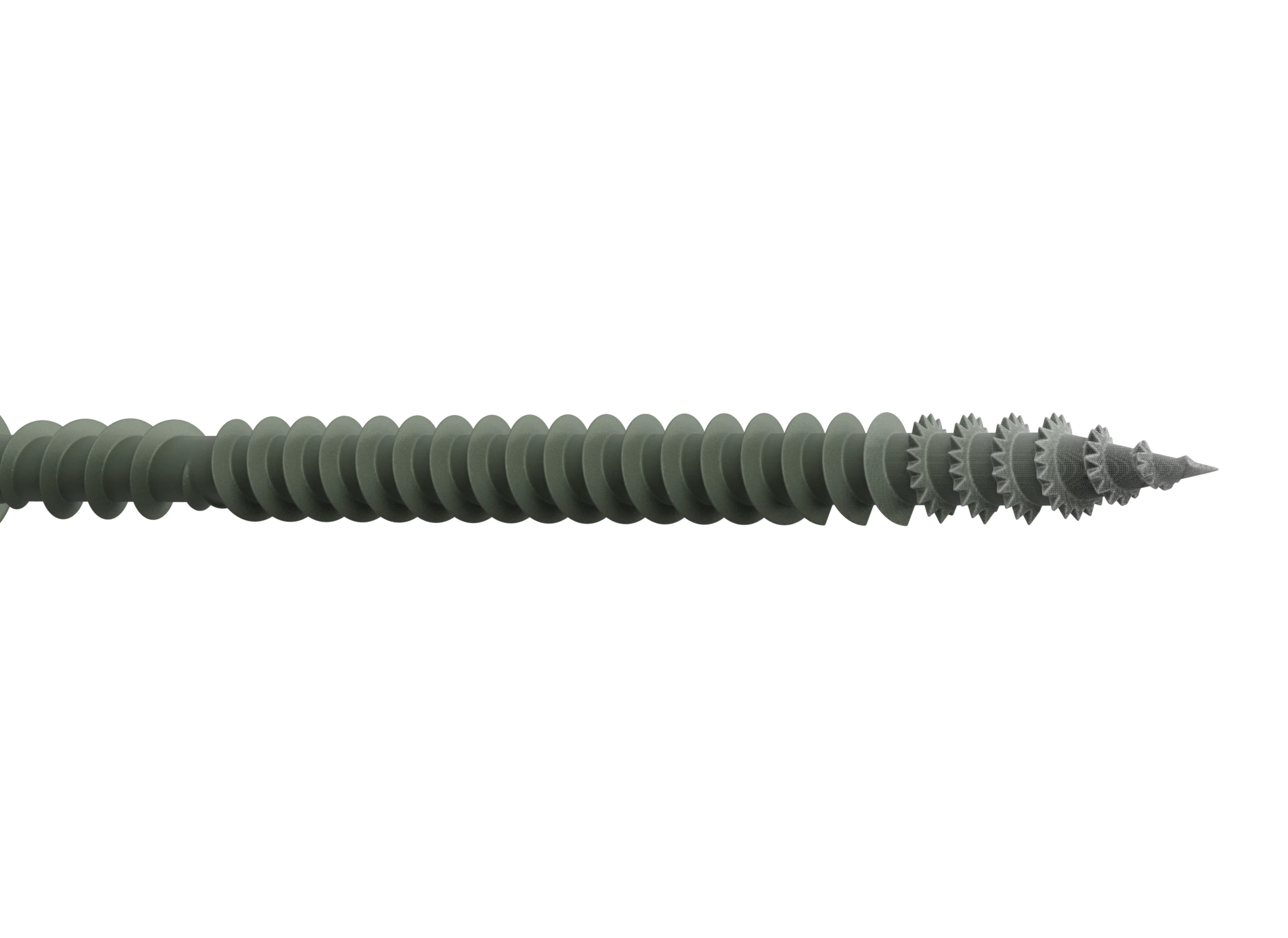

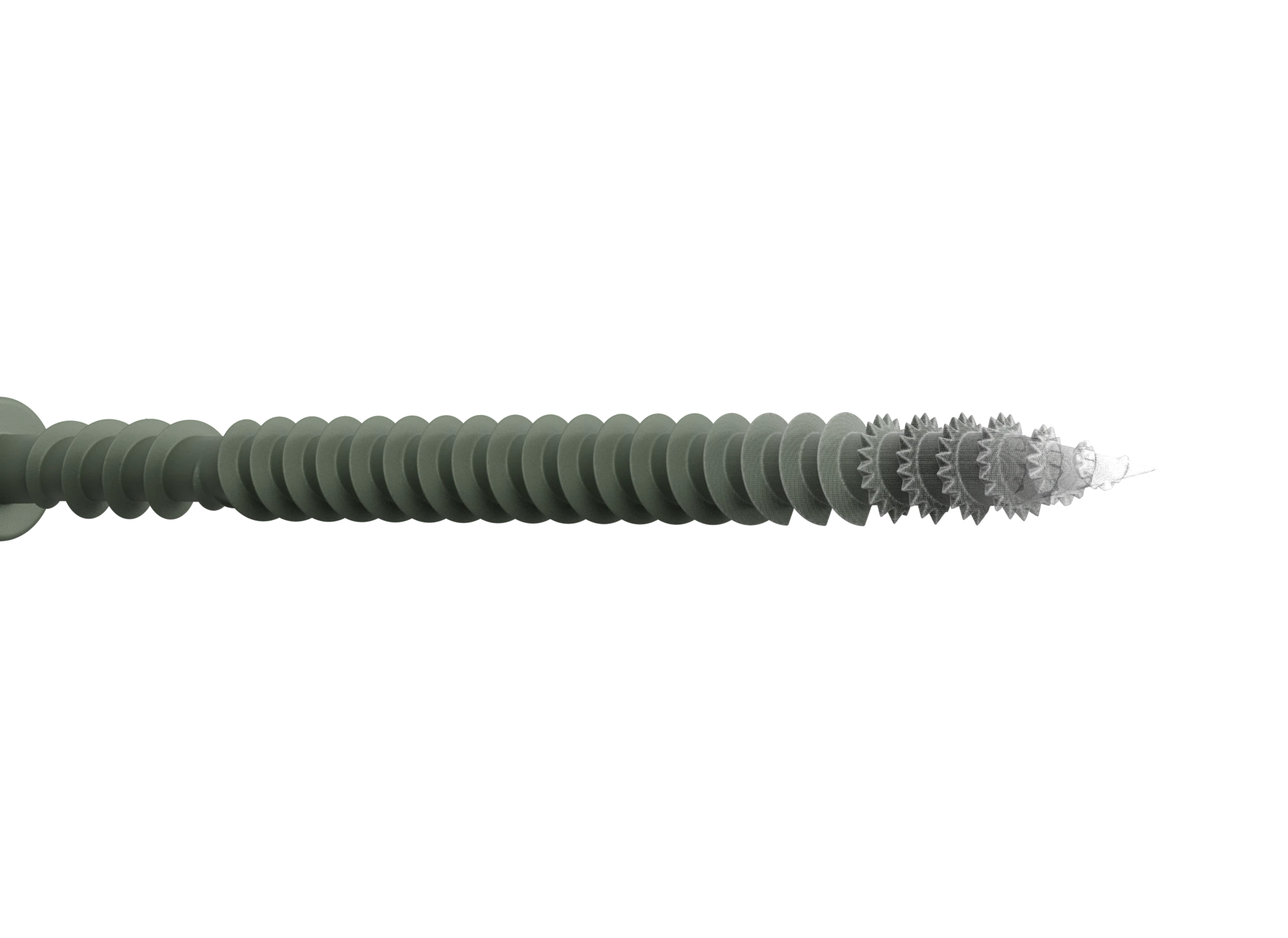

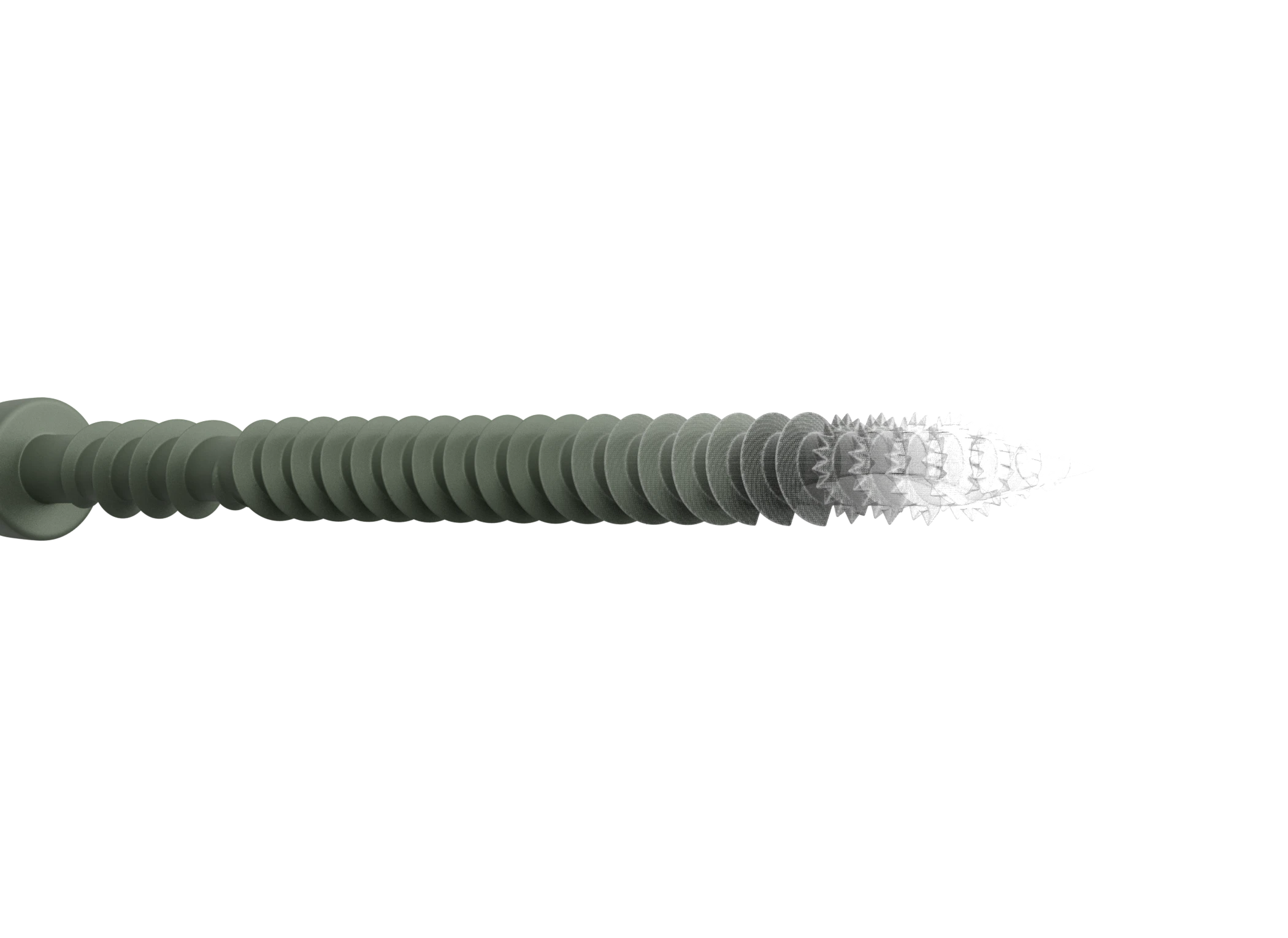

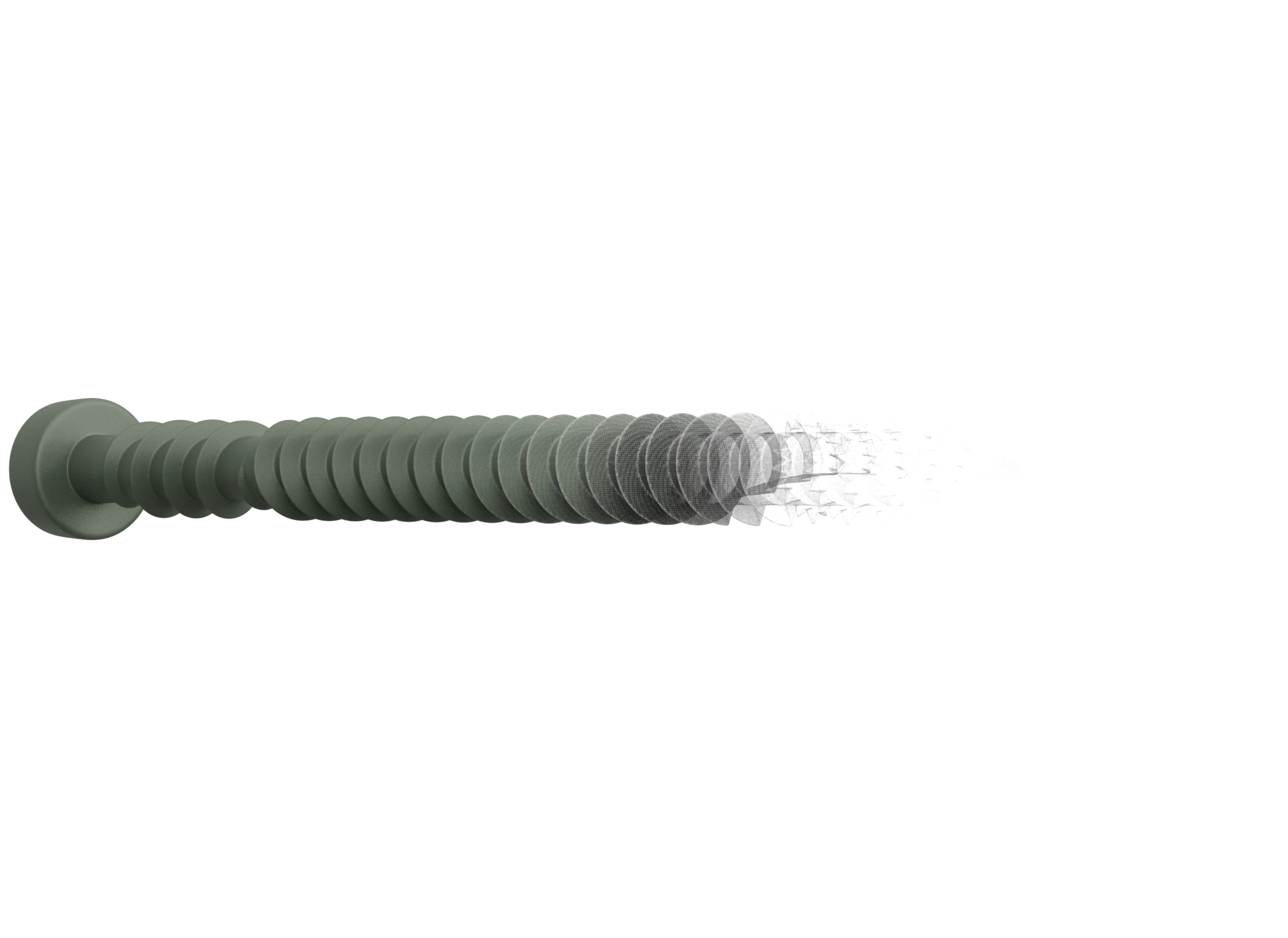

15 µm of nano treatment5 µm of anti-abrasive layer5-8 µm of white zinc coating Cr3 treatmentSteel substrateNANO COATINGIt is a non-organic tri-layer coating with a nano-treatment, an anti-abrasion layer, and a white zinc coating for high resistance to salt spray corrosion.10 µm of baked ceramic coating~2 µm high-corrosion-resistance chemical conversion film3-5 µm Metallic zinc layerSteel substrateENDURO COATINGIt is a non-organic tri-layer ceramic coating for high resistance to salt spray corrosion, consisting of fired ceramic coating, high corrosion resistance chemical conversion film, and a metallic zinc layer on the steel substrate.AESTHETIC FINISHES FOR YOUR EXCELLENCE PROJECTSAesthetic finishes embody the fusion of resistance and design. From innovative coatings to advanced material solutions, we delve into the details of finishes that stand out for elegance, resilience, and superior performance. Here are our options that allow you to add a touch of style while preserving the quality of your projects, reflecting your vision and ensuring lasting and extraordinary results.SUPER TOP ENDURO FINISHThis type of finish is primarily designed to provide exceptional corrosion resistance (1000 hours in salt spray), however, the finish presents an uniform and clean surface, without traces of corrosion or oxidation, which positively contributes to the aesthetic appearance of the screws. The main priority of this finish is corrosion resistance. SUPER TOP NANO FINISHThe 1000 hr Super Top Nano Treatment finish combines high-quality aesthetics with extraordinary corrosion resistance, making the screws suitable for projects where the emphasis is on both beauty and durability. These screws are ideal for projects where attention to design is crucial, allowing them to seamlessly integrate into the overall appearance of a product or structure. Our range of screws with the SUPER TOP NANO finish stands out for its versatility and style, with a selection of available colors: Gold, Brown, Green, Sand, and Gray; allowing you to choose the option that best suits the design of your project.

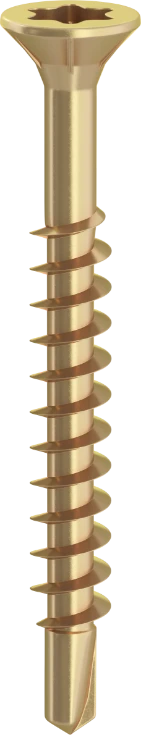

SUPER TOP NANO FINISHThe 1000 hr Super Top Nano Treatment finish combines high-quality aesthetics with extraordinary corrosion resistance, making the screws suitable for projects where the emphasis is on both beauty and durability. These screws are ideal for projects where attention to design is crucial, allowing them to seamlessly integrate into the overall appearance of a product or structure. Our range of screws with the SUPER TOP NANO finish stands out for its versatility and style, with a selection of available colors: Gold, Brown, Green, Sand, and Gray; allowing you to choose the option that best suits the design of your project. OTHER AESTHETIC FINISHESThese types of finishes are ideal for indoor use, offering various aesthetic options to seamlessly integrate them into various contexts and designs. The bronzed finish gives the screws a warm and rich appearance, adding a touch of elegance and tradition to the design. The nickel-plated finish provides a silvery and shiny surface, giving the screws a modern and clean look. The brass-plated finish has a golden, warm, and luxurious appearance reminiscent of brass metal.

OTHER AESTHETIC FINISHESThese types of finishes are ideal for indoor use, offering various aesthetic options to seamlessly integrate them into various contexts and designs. The bronzed finish gives the screws a warm and rich appearance, adding a touch of elegance and tradition to the design. The nickel-plated finish provides a silvery and shiny surface, giving the screws a modern and clean look. The brass-plated finish has a golden, warm, and luxurious appearance reminiscent of brass metal.

THE CHOICE BETWEEN THESE AESTHETIC FINISHES DEPENDS ON THE DESIRED STYLE FOR THE PROJECT AND SPECIFIC REQUIREMENTS IN TERMS OF CORROSION RESISTANCE. EACH OF THESE FINISHES CAN ADD A DISTINCTIVE TOUCH TO THE FINAL APPEARANCE OF THE SCREWS AND INFLUENCE THE OVERALL AESTHETICS OF THE APPLICATION IN WHICH THEY ARE USED.QUALITY CONTROL LABORATORYThe company places significant emphasis on the quality of its products, making the quality control laboratory the center of rigorous testing and inspections. In particular, salt spray resistance tests ensure that the materials meet the high standards required for use in harsh environments. All of this contributes to the reliability and excellence of Ambrovit products.

THE CHOICE BETWEEN THESE AESTHETIC FINISHES DEPENDS ON THE DESIRED STYLE FOR THE PROJECT AND SPECIFIC REQUIREMENTS IN TERMS OF CORROSION RESISTANCE. EACH OF THESE FINISHES CAN ADD A DISTINCTIVE TOUCH TO THE FINAL APPEARANCE OF THE SCREWS AND INFLUENCE THE OVERALL AESTHETICS OF THE APPLICATION IN WHICH THEY ARE USED.QUALITY CONTROL LABORATORYThe company places significant emphasis on the quality of its products, making the quality control laboratory the center of rigorous testing and inspections. In particular, salt spray resistance tests ensure that the materials meet the high standards required for use in harsh environments. All of this contributes to the reliability and excellence of Ambrovit products. IN OUR QUALITY LABControl, methodology, and quality: a perfect affinityAmbrovit quality control laboratory is a crucial hub for submitting products to rigorous testsOne of the main drivers of the company is the quality of the offered product, along with the breadth of the range available in stock in the screw and bolt segments, ready for order fulfillment. Uncompromising quality involves the entire variety of products, both in the types of screws and bolts and in finishes and galvanic processes, and it must be constantly monitored.

IN OUR QUALITY LABControl, methodology, and quality: a perfect affinityAmbrovit quality control laboratory is a crucial hub for submitting products to rigorous testsOne of the main drivers of the company is the quality of the offered product, along with the breadth of the range available in stock in the screw and bolt segments, ready for order fulfillment. Uncompromising quality involves the entire variety of products, both in the types of screws and bolts and in finishes and galvanic processes, and it must be constantly monitored.In Ambrovit, the quality control laboratory, a long-standing presence in the company, is a fundamental department, a crucial hub for subjecting new products to the most rigorous tests. It is equipped with the most sophisticated advanced instruments and innovative statistical software, in line with European parameters, to ensure the functioning and reliability of the collected results.

For this reason, the equipment undergoes specific checks and calibrations in compliance with management procedures and the UNI EN ISO 9001 standard.

SALT SPRAY TESTMonitoring and control in aggressive environments that make a differenceWe verify each of our products with a test that checks resistance in challenging outdoor environments.Samples are placed inside a test chamber, where they are exposed to a constant and dense mist composed of a saline solution. This mist contains chlorides, which are known to accelerate the corrosion process. The samples remain exposed to these adverse conditions for a specific period.

SALT SPRAY TESTMonitoring and control in aggressive environments that make a differenceWe verify each of our products with a test that checks resistance in challenging outdoor environments.Samples are placed inside a test chamber, where they are exposed to a constant and dense mist composed of a saline solution. This mist contains chlorides, which are known to accelerate the corrosion process. The samples remain exposed to these adverse conditions for a specific period.Quality control in a salt spray test is essential to verify the corrosion resistance of materials and products. During the test, samples are subjected to simulated conditions of accelerated corrosion in a salt spray chamber. Experts continuously monitor the samples to assess any signs of corrosion and ensure that the test is conducted accurately, producing reliable results. This quality control is crucial to ensure that materials and products meet the corrosion resistance standards required for use in harsh environments.

LABORATORY TESTIn the Quality Control Laboratory are available the following instruments:HITECH EUROPE C 250 SMiter sawHitech Europe EP 15BalerHitech Europe AP 21VCleanserFuture Tech FR-3 ERockwell hardness testing machineFuture Tech FV 300Vickers hardness meter and dedicated softwareNikon SMZ 745 TStereomicroscope and dedicated softwareKarl Deutsch Leptoskop 2042Thickness gaugeNikon MP-V12ProjectorDeltafluxDrilling test machine and dedicated softwareCorrosionboxFor salt spray test according to ISO~DIN THE PILLARS OF OUR QUALITY:

THE PILLARS OF OUR QUALITY:

COMPLIANCE-PERFORMANCE-DISTINCTIONTHE PILLARS OF OUR QUALITY:

COMPLIANCE

PERFORMANCE

DISTINCTIONAmbrovit is characterized by three essentials, interconnected, and harmonized values , creating a distinctive presence in a global market and a challenging economic context.

COMPLIANCEExplore our certificationsCommitment to quality is a priority permeating every aspect of the company. This commitment led us to achieve certification for the Quality Management System in 2011.

PERFORMANCEExplore the wide range of certified productsWe have one goal: to achieve excellence in each of the reference sectors of our products, ensuring international certification and meeting the needs of an ever-expanding clientele.

DISTINCTIONAesthetic and durable finishesAmbrovit’s dedication to quality translates into refined process optimization, involving a wide range of products and offering customization options in both aesthetic finishes and galvanic processes. This results in unique solutions designed to withstand the time passing.

QUALITY IS NOT JUST A NOTION.Over time, quality has become a fundamental driver involving every department and led the company to achieve Quality Management System certification in 2011. Most products are equipped with various certifications depending on their type and intended use. Additional quality control tests are conducted in-house in our internal laboratory in collaboration with the University of Trento.

Ambrovit has achieved ISO 9001 certification, a recognition of quality and safety. To attain this certification, the company must demonstrate adherence to criteria such as advanced quality control, regulatory compliance, use of high-quality materials, product safety, and environmental commitment. Sustaining the certification demands a continuous dedication to improvement. This seal of approval serves as a robust indicator of reliability and quality, capable of bolstering customer confidence.

TÜV SÜD conducts periodic surveillance audits on all production processes, ensuring compliance with all requirements mandated by international regulations. Among these, the Euronorm 14592 is particularly relevant, and involves wood structures and connecting cylindrical elements. The standard outlines requirements and testing methods for materials, geometry, strength, rigidity, and durability of connecting cylindrical elements used in load-bearing wooden structures. ISO 9001 certification serves as a seal of approval that highlights a manufacturing company’s consistent commitment to providing products of the highest quality, safety, and reliability. These products adhere to current regulations and are at the forefront of the industry. This recognition becomes a powerful marketing tool, assuring buyers that the products have undergone rigorous quality checks by an international organization.LEARN MORE

TÜV SÜD conducts periodic surveillance audits on all production processes, ensuring compliance with all requirements mandated by international regulations. Among these, the Euronorm 14592 is particularly relevant, and involves wood structures and connecting cylindrical elements. The standard outlines requirements and testing methods for materials, geometry, strength, rigidity, and durability of connecting cylindrical elements used in load-bearing wooden structures. ISO 9001 certification serves as a seal of approval that highlights a manufacturing company’s consistent commitment to providing products of the highest quality, safety, and reliability. These products adhere to current regulations and are at the forefront of the industry. This recognition becomes a powerful marketing tool, assuring buyers that the products have undergone rigorous quality checks by an international organization.LEARN MOREETA (European Technical Assessment) certification is a European process of technical evaluation that assesses and approves the suitability of construction products in compliance with European regulations. This procedure is particularly relevant for the building and construction industry. The ETA certification process involves a comprehensive technical assessment by notified bodies, which examine products based on technical requirements and performance criteria.

ETA certification is voluntary and serves as a way to demonstrate product compliance with European technical specifications, especially when CE standard regulations are not directly applicable or complete.

ETA certification is voluntary and serves as a way to demonstrate product compliance with European technical specifications, especially when CE standard regulations are not directly applicable or complete.

Ambrovit proudly holds the ETA 16/0381 Certification for its entire range of carpentry screws, the ETA 18/1065 Option 1 Certification for anchoring screws in concrete, and the Post R Certificate of Conformity and Safety.

Once an ETA certification is obtained, products can be marketed in all European Union countries, facilitating their acceptance in the European market and transparently showcasing compliance with required technical standards. ETA certification is essential to ensure the quality and safety of construction products and to promote the free movement of goods within the EU.LEARN MOREPRODUCTS CERTIFICATIONSInternational complianceQuality in Ambrovit is a value that must be measured and confirmed through certifications issued by international certifying agency.

The whole range of products is tested, both the different types of screws and bolts as well as the different finishes and treatments.18,000+CERTIFIED REFERENCESAmong our certifications, it’s included the Euronorm 14592, which provides dimensional parameters, tests to be performed, and quality control procedures that the product must meet to be declared compliant and marked with CE. The company also holds ETA Certification 16/0381 for the entire range of carpentry screws; ETA Certification 18/1065 Option 1 for anchoring concrete screws.REGULATIONSWithin the technical standards of industrial sectorsFastening elements have the task of transferring loads to the supporting material in which they are installed. Therefore, the standardization and conformity of each individual element become fundamental. Let’s see what the main ones are and how they differ from each other.DINIt is a technical standard issued by the German Deutsches Institut für Normung, which means that there is no obligation of application. Essentially, they are private standards with a recommendation character.UNIIt is the acronym for the Italian National Unification Body, a private association that develops and publishes technical standards for all industrial sectors. It represents Italy in European (CEN) and global (ISO) standardization organizations.ISOIt is the acronym that identifies standards developed by ISO, the International Organization for Standardization. These standards are applicable worldwide. Each country can decide whether to adopt them as national standards.GALVANIC TREATMENTSOur galvanic treatments ensure reliable performance in outdoor environments and challenging conditions.AESTHETIC FINISHESElegance and design: aesthetic finishes add a touch of style to every project without compromising durability and performance.

40µm HOT DIP GALVANIZED“Hot Dip Galvanized” is the hot-dip galvanizing process by immersion in molten zinc. This specification makes the screws highly resistant to corrosion, as in external structures, bridges, maritime structures, and other applications in challenging environments.400hr HIGH TOPThrough special treatments, these screws with a resistance of 400 hours are an excellent choice for applications that require reliable protection against corrosion in humid environments or exposure to corrosive substances.120hr TOPWith a thicker zinc layer of 8 microns, the corrosion resistance in hours increases. In this case, “120 hr” indicates that the screws have been designed to withstand corrosion in a standard test environment for at least 120 hours.72hr MEDIUMThe CR3 zinc coating is designed to provide good corrosion resistance in many applications, while a thicker zinc layer of more than 5 microns can offer better corrosion protection.48hr PHOSPHATEDPhosphated finish is a surface coating often used for screws and other metal components. The final result is not known to be aesthetically appealing or decorative, but mainly to provide anti-corrosion and anti-friction functions.36hr YELLOWYellow zinc plating is a variation of the zinc plating process that uses a special passivate to achieve a yellow color on the zinc-coated surface. This type of finish is often used for aesthetic purposes or for visual recognition of components.24hr BASEA 3-micron finish is considered thick enough for effective corrosion protection in many applications. A thicker zinc layer provides better protection and resistance.BLACKZNC CR3″ is a specification indicating that the screws have been zinc-coated with a layer of zinc (ZNC) according to a standard that provides moderate corrosion resistance (CR3). This type of finish is commonly used to protect screws in normal environments.The RoHS directive, staying for Restriction of Hazardous Substances, is a European law that limits the use of certain harmful substances in the manufacturing of commercial products. This regulation safeguards the quality of life and the environment by reducing the content of harmful substances such as lead, mercury, cadmium, and others. Compliance with the RoHS directive is synonymous with quality for marketing products in the European Union, thereby contributing to the promotion of the adoption of safer and more sustainable technologies.AESTHETIC FINISHES FOR YOUR EXCELLENCE PROJECTSAesthetic finishes embody the fusion of resistance and design. From innovative coatings to advanced material solutions, we delve into the details of finishes that stand out for elegance, resilience, and superior performance. Here are our options that allow you to add a touch of style while preserving the quality of your projects, reflecting your vision and ensuring lasting and extraordinary results.SUPER TOP ENDURO FINISHThis type of finish is primarily designed to provide exceptional corrosion resistance (1000 hours in salt spray), however, the finish presents an uniform and clean surface, without traces of corrosion or oxidation, which positively contributes to the aesthetic appearance of the screws. The main priority of this finish is corrosion resistance.

40µm HOT DIP GALVANIZED“Hot Dip Galvanized” is the hot-dip galvanizing process by immersion in molten zinc. This specification makes the screws highly resistant to corrosion, as in external structures, bridges, maritime structures, and other applications in challenging environments.400hr HIGH TOPThrough special treatments, these screws with a resistance of 400 hours are an excellent choice for applications that require reliable protection against corrosion in humid environments or exposure to corrosive substances.120hr TOPWith a thicker zinc layer of 8 microns, the corrosion resistance in hours increases. In this case, “120 hr” indicates that the screws have been designed to withstand corrosion in a standard test environment for at least 120 hours.72hr MEDIUMThe CR3 zinc coating is designed to provide good corrosion resistance in many applications, while a thicker zinc layer of more than 5 microns can offer better corrosion protection.48hr PHOSPHATEDPhosphated finish is a surface coating often used for screws and other metal components. The final result is not known to be aesthetically appealing or decorative, but mainly to provide anti-corrosion and anti-friction functions.36hr YELLOWYellow zinc plating is a variation of the zinc plating process that uses a special passivate to achieve a yellow color on the zinc-coated surface. This type of finish is often used for aesthetic purposes or for visual recognition of components.24hr BASEA 3-micron finish is considered thick enough for effective corrosion protection in many applications. A thicker zinc layer provides better protection and resistance.BLACKZNC CR3″ is a specification indicating that the screws have been zinc-coated with a layer of zinc (ZNC) according to a standard that provides moderate corrosion resistance (CR3). This type of finish is commonly used to protect screws in normal environments.The RoHS directive, staying for Restriction of Hazardous Substances, is a European law that limits the use of certain harmful substances in the manufacturing of commercial products. This regulation safeguards the quality of life and the environment by reducing the content of harmful substances such as lead, mercury, cadmium, and others. Compliance with the RoHS directive is synonymous with quality for marketing products in the European Union, thereby contributing to the promotion of the adoption of safer and more sustainable technologies.AESTHETIC FINISHES FOR YOUR EXCELLENCE PROJECTSAesthetic finishes embody the fusion of resistance and design. From innovative coatings to advanced material solutions, we delve into the details of finishes that stand out for elegance, resilience, and superior performance. Here are our options that allow you to add a touch of style while preserving the quality of your projects, reflecting your vision and ensuring lasting and extraordinary results.SUPER TOP ENDURO FINISHThis type of finish is primarily designed to provide exceptional corrosion resistance (1000 hours in salt spray), however, the finish presents an uniform and clean surface, without traces of corrosion or oxidation, which positively contributes to the aesthetic appearance of the screws. The main priority of this finish is corrosion resistance. SUPER TOP NANO FINISHThe 1000 hr Super Top Nano Treatment finish combines high-quality aesthetics with extraordinary corrosion resistance, making the screws suitable for projects where the emphasis is on both beauty and durability. These screws are ideal for projects where attention to design is crucial, allowing them to seamlessly integrate into the overall appearance of a product or structure. Our range of screws with the SUPER TOP NANO finish stands out for its versatility and style, with a selection of available colors: Gold, Brown, Green, Sand, and Gray; allowing you to choose the option that best suits the design of your project.

SUPER TOP NANO FINISHThe 1000 hr Super Top Nano Treatment finish combines high-quality aesthetics with extraordinary corrosion resistance, making the screws suitable for projects where the emphasis is on both beauty and durability. These screws are ideal for projects where attention to design is crucial, allowing them to seamlessly integrate into the overall appearance of a product or structure. Our range of screws with the SUPER TOP NANO finish stands out for its versatility and style, with a selection of available colors: Gold, Brown, Green, Sand, and Gray; allowing you to choose the option that best suits the design of your project. OTHER AESTHETIC FINISHESThese types of finishes are ideal for indoor use, offering various aesthetic options to seamlessly integrate them into various contexts and designs. The bronzed finish gives the screws a warm and rich appearance, adding a touch of elegance and tradition to the design. The nickel-plated finish provides a silvery and shiny surface, giving the screws a modern and clean look. The brass-plated finish has a golden, warm, and luxurious appearance reminiscent of brass metal.

OTHER AESTHETIC FINISHESThese types of finishes are ideal for indoor use, offering various aesthetic options to seamlessly integrate them into various contexts and designs. The bronzed finish gives the screws a warm and rich appearance, adding a touch of elegance and tradition to the design. The nickel-plated finish provides a silvery and shiny surface, giving the screws a modern and clean look. The brass-plated finish has a golden, warm, and luxurious appearance reminiscent of brass metal.

THE CHOICE BETWEEN THESE AESTHETIC FINISHES DEPENDS ON THE DESIRED STYLE FOR THE PROJECT AND SPECIFIC REQUIREMENTS IN TERMS OF CORROSION RESISTANCE. EACH OF THESE FINISHES CAN ADD A DISTINCTIVE TOUCH TO THE FINAL APPEARANCE OF THE SCREWS AND INFLUENCE THE OVERALL AESTHETICS OF THE APPLICATION IN WHICH THEY ARE USED.QUALITY CONTROL LABORATORYThe company places significant emphasis on the quality of its products, making the quality control laboratory the center of rigorous testing and inspections. In particular, salt spray resistance tests ensure that the materials meet the high standards required for use in harsh environments. All of this contributes to the reliability and excellence of Ambrovit products.

THE CHOICE BETWEEN THESE AESTHETIC FINISHES DEPENDS ON THE DESIRED STYLE FOR THE PROJECT AND SPECIFIC REQUIREMENTS IN TERMS OF CORROSION RESISTANCE. EACH OF THESE FINISHES CAN ADD A DISTINCTIVE TOUCH TO THE FINAL APPEARANCE OF THE SCREWS AND INFLUENCE THE OVERALL AESTHETICS OF THE APPLICATION IN WHICH THEY ARE USED.QUALITY CONTROL LABORATORYThe company places significant emphasis on the quality of its products, making the quality control laboratory the center of rigorous testing and inspections. In particular, salt spray resistance tests ensure that the materials meet the high standards required for use in harsh environments. All of this contributes to the reliability and excellence of Ambrovit products. IN OUR QUALITY LABControl, methodology, and quality: a perfect affinityAmbrovit quality control laboratory is a crucial hub for submitting products to rigorous testsOne of the main drivers of the company is the quality of the offered product, along with the breadth of the range available in stock in the screw and bolt segments, ready for order fulfillment. Uncompromising quality involves the entire variety of products, both in the types of screws and bolts and in finishes and galvanic processes, and it must be constantly monitored.

IN OUR QUALITY LABControl, methodology, and quality: a perfect affinityAmbrovit quality control laboratory is a crucial hub for submitting products to rigorous testsOne of the main drivers of the company is the quality of the offered product, along with the breadth of the range available in stock in the screw and bolt segments, ready for order fulfillment. Uncompromising quality involves the entire variety of products, both in the types of screws and bolts and in finishes and galvanic processes, and it must be constantly monitored.In Ambrovit, the quality control laboratory, a long-standing presence in the company, is a fundamental department, a crucial hub for subjecting new products to the most rigorous tests. It is equipped with the most sophisticated advanced instruments and innovative statistical software, in line with European parameters, to ensure the functioning and reliability of the collected results.

For this reason, the equipment undergoes specific checks and calibrations in compliance with management procedures and the UNI EN ISO 9001 standard.

SALT SPRAY TESTMonitoring and control in aggressive environments that make a differenceWe verify each of our products with a test that checks resistance in challenging outdoor environments.Samples are placed inside a test chamber, where they are exposed to a constant and dense mist composed of a saline solution. This mist contains chlorides, which are known to accelerate the corrosion process. The samples remain exposed to these adverse conditions for a specific period.

SALT SPRAY TESTMonitoring and control in aggressive environments that make a differenceWe verify each of our products with a test that checks resistance in challenging outdoor environments.Samples are placed inside a test chamber, where they are exposed to a constant and dense mist composed of a saline solution. This mist contains chlorides, which are known to accelerate the corrosion process. The samples remain exposed to these adverse conditions for a specific period.Quality control in a salt spray test is essential to verify the corrosion resistance of materials and products. During the test, samples are subjected to simulated conditions of accelerated corrosion in a salt spray chamber. Experts continuously monitor the samples to assess any signs of corrosion and ensure that the test is conducted accurately, producing reliable results. This quality control is crucial to ensure that materials and products meet the corrosion resistance standards required for use in harsh environments.

LABORATORY TESTIn the Quality Control Laboratory are available the following instruments:HITECH EUROPE C 250 SMiter sawHitech Europe EP 15BalerHitech Europe AP 21VCleanserFuture Tech FR-3 ERockwell hardness testing machineFuture Tech FV 300Vickers hardness meter and dedicated softwareNikon SMZ 745 TStereomicroscope and dedicated softwareKarl Deutsch Leptoskop 2042Thickness gaugeNikon MP-V12ProjectorDeltafluxDrilling test machine and dedicated softwareCorrosionboxFor salt spray test according to ISO~DIN